g-tech electronics

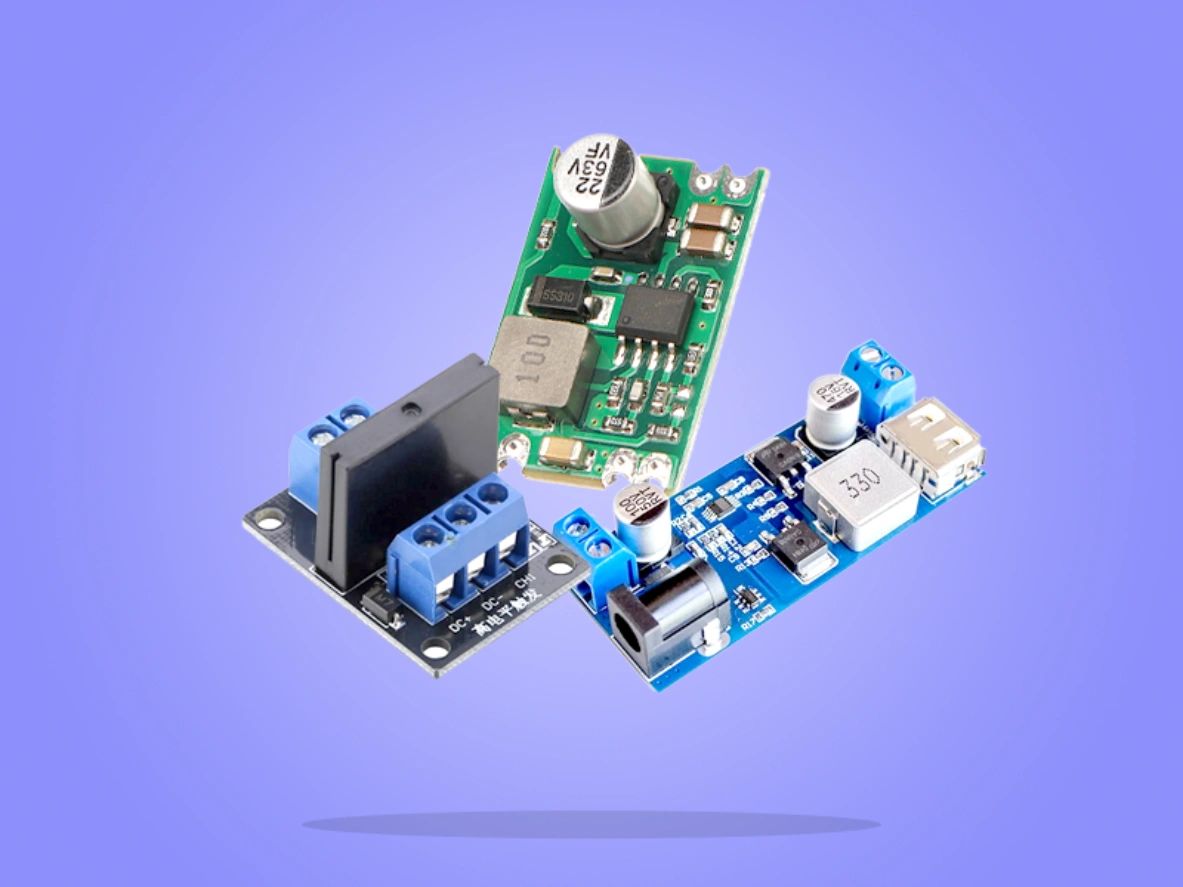

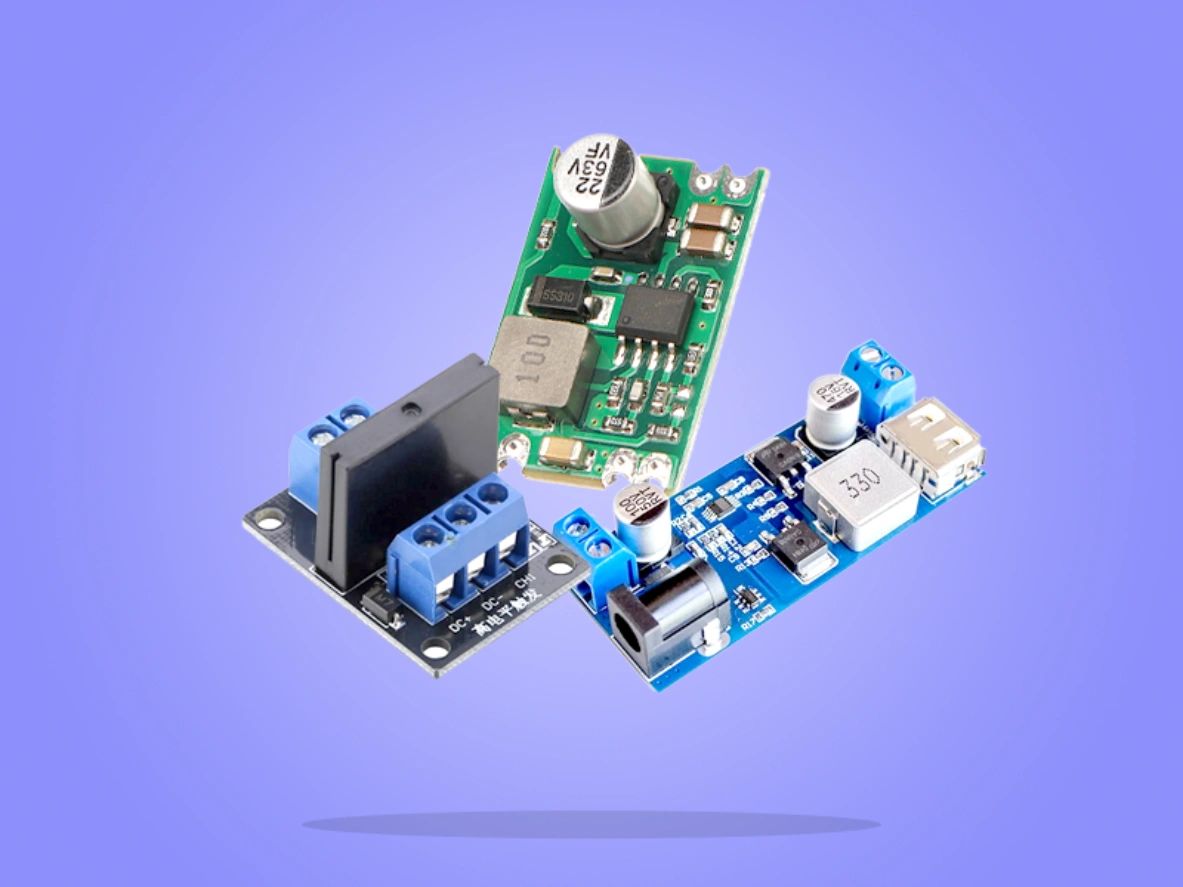

Modules, Controllers and Logic drivers electronics electronic technology new electronics, PCB Designs, 3d printing services, best pcb design, electronics solutions,

Modules, Controllers and Logic drivers electronics electronic technology new electronics, PCB Designs, 3d printing services, best pcb design, electronics solutions,

We begin by thoroughly understanding the customer's requirements through detailed discussions and planning. Our team collaborates closely to identify the specific electronic solutions needed for their project. This includes analyzing functionality, performance, and design expectations. We ensure clear communication to align on goals and deliverables. This step sets the foundation for a successful and customized solution.

In this stage, we create a detailed plan outlining the entire project timeline, ensuring every milestone is clearly defined. We provide a comprehensive quotation, including pricing for all components and services. Our team ensures transparency by specifying what can be achieved within the scope of the project. We also address any potential challenges and propose solutions upfront. This step ensures the customer has a clear understanding of the process, costs, and deliverables.

Our team specializes in designing industrial-grade PCBs tailored to meet customer requirements with precision and reliability. We ensure the design adheres to industry standards for performance, durability, and safety. Advanced tools and techniques are used to optimize the layout for efficiency and functionality. Every design is reviewed and tested to ensure seamless integration into the final product. This stage guarantees a high-quality PCB ready for manufacturing and assembly.

We specialize in high-precision SMT soldering to ensure the reliable assembly of electronic components. Our team selects only the best components from trusted suppliers like DigiKey and Mouser to guarantee quality and performance. Advanced assembly techniques are employed to meet industrial standards and customer expectations. Each product undergoes rigorous inspection to ensure flawless functionality. This step ensures a robust and efficient electronic assembly for your project.

We design custom enclosures tailored to your specific requirements, using 3D modeling to create precise, functional designs. With in-house 3D printing capabilities, we quickly produce prototypes to validate the fit and functionality of the enclosure. We utilize SLA (Stereolithography) technology to ensure the final product is strong, durable, and aesthetically pleasing. This process mimics the look and feel of vacuum casting, delivering high-quality enclosures with excellent finish and strength. The result is a custom solution that perfectly houses your module while meeting all design and durability standards.

Before delivery, we conduct thorough testing across all voltage and current standards to ensure the product meets the required specifications and performs flawlessly. Our rigorous testing process guarantees the reliability and functionality of the final product. We ensure everything is in perfect working condition before shipping. On-time delivery is a priority, and we take every measure to meet deadlines while maintaining the highest quality standards. The result is a product that is fully tested, reliable, and delivered as promised.

Copyright © 2025 G-Tech Solution - All Rights Reserved.